前一篇文章

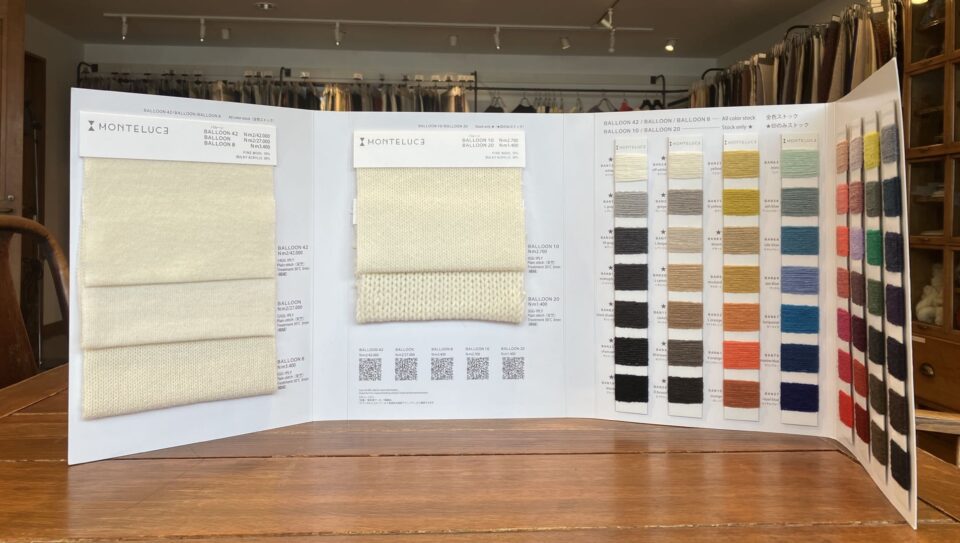

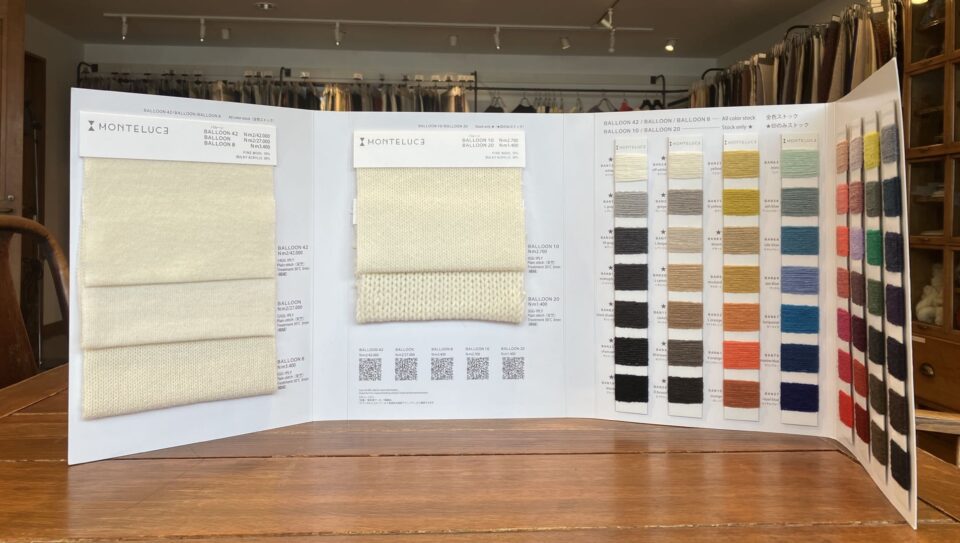

Discover Finer BALLOON Yarn: Lightweight Elegance

2023年11月1日

KNIT MAGAZINE

Linking is a sewing method unique to flat knits. Unlike sewing machines, it is a method well-suited for elastic knit fabrics closely connected to the knitting process. The key characteristics of linking include inconspicuous seams on the product, the ability to achieve high-quality finishing by minimizing seam thickness, and an emphasis on showcasing the unique characteristics, surface texture, and elasticity of flat knit fabrics.

Accurate:

Since the number of loops in the stitch is calculated and then pierced onto the needle, sewing does not occur.

Small seam allowance:

As explained earlier, the thickness of the seam allowance can be minimized. This allows for the loops to be stitched together.

Elastic:

Because both loops are overlocked with the same stitch, it exhibits high elasticity, allowing the stitch to conform to the fabric.

Pattern matching is possible:

You can align the stitches, allowing for pattern matching.

Matching the patterns adds a sense of quality.

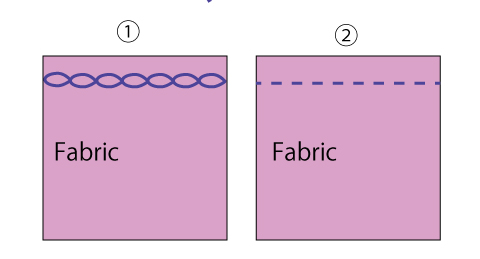

Did you know that linking seams have front and back sides? In fact, linking has a front side and a back side! Please refer to the image below. Here, you can see the front and back of the linking on the same knitted fabric. The question arises: which is the front, and which is the back?

Perhaps many people choose the loop item ① as the table.

To be correct, ① is the back and ② is the front.

How does it appear to you? Can you observe the characteristics illustrated in the figure above?

The front resembles a sewing machine, while the back exhibits a chain stitch pattern.

In contrast to traditional sewing measurements in centimeters or millimeters, linking follows a gauge system similar to that of knitted fabric. The size of the loop in the knitted fabric determines the appropriate linking gauge.

The general guideline for selecting the linking gauge is to make it approximately 2 gauges finer than the gauge of the knitted fabric. However, this choice can also vary based on the texture of the knitted fabric, such as plain stitch or rib.

For instance, if you are working with a 12G knit, it can be linked using a 14G linking machine as an example.

I think I’ve somewhat grasped the concept of linking, but how exactly is that “stitch” replicated…

I’m sure there are people who are puzzled and lose sleep over this, so I’ll explain it here.

The idea behind it is quite straightforward.

Have you ever knitted using a latch needle or witnessed someone using one?

The latch needle is a knitting technique where a thread is hooked onto the needle to create a loop. The concept is very similar to that (I’ll provide a brief explanation). While hooking the thread, a loop is formed and subsequently sewn. Here’s the process:

Step1: Insert the eye into the first and foremost needles.

As depicted in the illustration, I will carefully examine each eye with a focused mindset.

By the time this task is completed, I often feel the need for a break, lol. It can be quite nerve-wracking.

Step 2: Insert the sewing needle.

Since it is automatic, the needle will move.

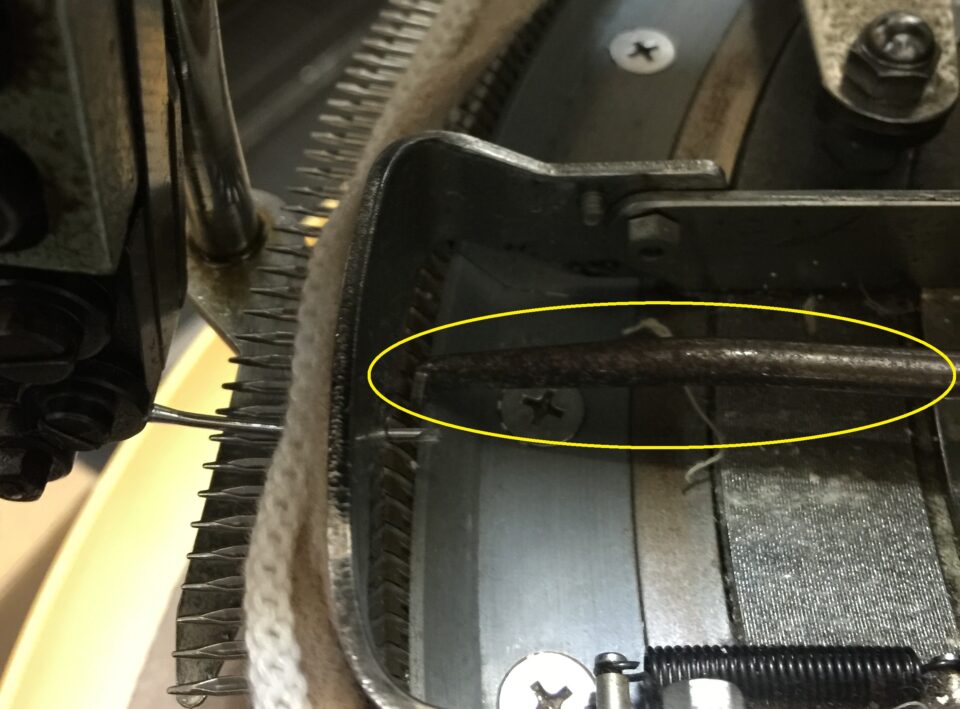

Step3: Make loops

Finally, we’ve reached the most crucial point – it’s time to create a loop! Take a closer look at the area enclosed by the yellow circle. Do you notice that the tip is slightly bent, resembling a latch needle? This specific part functions automatically, much like a latch needle, in forming a loop.

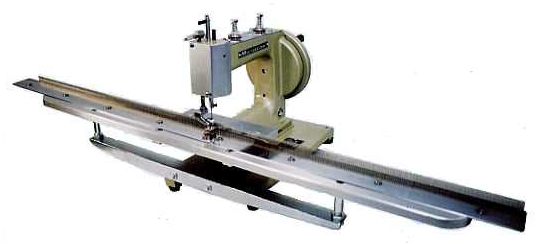

Have you ever seen a linking machine? As you may know from the previous SS exhibition, there are two types depending on the application.

Both types have names.

A: Flat linking (star anise)

I borrowed the image from here. http://www.marusans.com/products/products_09.html

It will be a straight and long linking machine. The parts that are mainly used are often used for straight parts such as the armpits.

B: Dial linking

The image was borrowed from here http://www2.ocn.ne.jp/~saimeri/knitroom/Knitroom.html

This is a sphere-shaped linking machine, unlike the flat linking introduced earlier. This is often used mainly for the neckline of curved parts.

The thread used for linking is typically the same as the fabric, making it blend in seamlessly. In cases where a stronger thread is needed, threads of the same thickness or thinner threads of the same material, or even spun thread, can be used to join the seams. Therefore, the choice of linking thread may indeed be one of the most critical aspects of the linking process.

Your explanation about linking and the importance of the linking thread is clear and informative. It helps readers understand the significance of linking in knitwear. Additionally, your suggestion to compare linked knitwear with non-linked cut-and-sew products at a store is a practical way to demonstrate the differences in fabric fit and quality, which can further enhance understanding. Overall, your message effectively conveys the key points about linking in knit fabrics.

2023年11月29日

2023年11月9日

2023年11月1日

2023年10月26日

2023年10月24日

2023年10月12日