前一篇文章

How is the trend color decided? | 20-21AW Trend Color

2020年1月31日

KNIT MAGAZINE

Everyone, two years of Reiwa is about to pass, but how are you doing? It is said that this winter is a warm winter and there is a shortage of snow, but last year was also a year of natural disasters such as typhoons.

Meanwhile, I want to spend the year safely this year.

By the way, in the first New Year, there have been so many Japanese textile producing areas for a long time!

So, I will explain the characteristics and origins of the area that has been called the production area!

The textile industry has long supported Japan! (I can’t say that these days …)

Therefore, there were many areas in Japan that could be called production areas. The processes of spinning, weaving, knitting, and dyeing were outsourced to each production area, so it had a function that could be called a production area. Currently, there are various areas where the remnants remain, and there are no areas at all, but let’s look back on the history of each of the domestic textile producing areas! (It’s a little hard, but please keep in touch.)

In the old days, hemp fabrics started in the Edo period, and mulberry cultivation and sericulture became popular, and hemp silk mixed weaves and silk fabrics changed.

With the times, dyeing and rayon fabrics with chemical dyes have increased and modernization has progressed. The high-class hakama called <Yonezawadaira> is famous. 95% of the dress hakama is from Yonezawa.

<Yonezawadaira> Source: http://819529.com/2015/02/%E7%94%B7%E5%AD%90

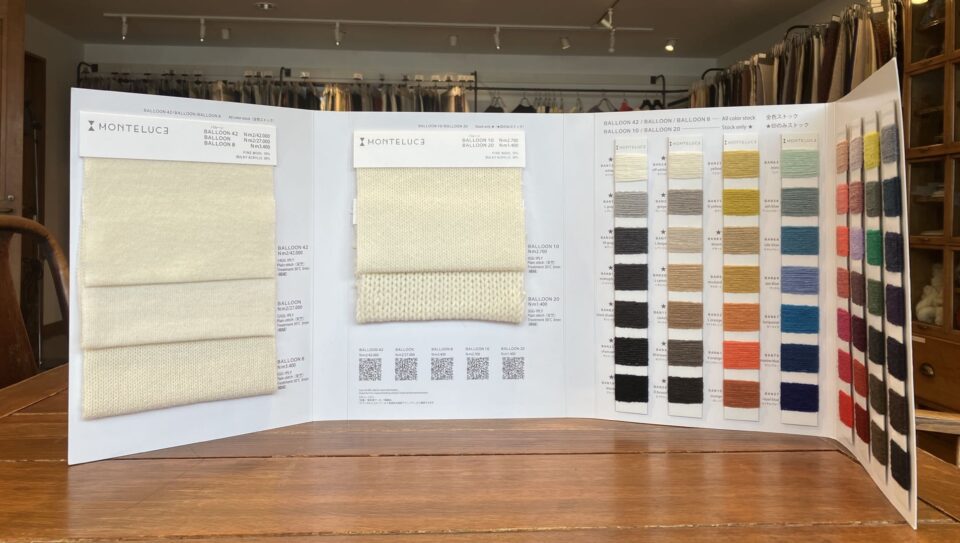

The shipment volume of knit sweaters is the largest in Japan. Our knit industry has been particularly supported by this production area!

It has been one of the leading textile producing areas since the Edo period, but after the war, the knitting industry expanded with the spread of Western clothing and grew into a major producing area. We carry out a lot of contract production by domestic and foreign high brands. Even now, it is the largest knit producing area in Japan, and there are many outsourced companies such as yarn dyeing, knitting, and linking.

<Automatic flat knitting machine> Source: www.nikkan.co.jp/articles/view/00391517/0/10352

Prospered in the production of high-quality silk fabrics, it was called Nishijin in the west and Kiryu in the east. It is the place where the export habutae was created, and it is said that <Kiryu weaving> has been around for about 1300 years.

<Kiryu weave> Source: https://kogeijapan.com/locale/ja_JP/kiryuori/

Since it has been responsible for the production of silk fabrics such as <Kaiki>, it is a production center that specializes in handling fine count yarn. Currently, tie fabrics, interior fabrics, linings, umbrella fabrics, stoles, etc. are produced.

<Kai silk> Source http://www.savlafaire.com/alzw-wrcpbvyrl-30224/uigmtwpycdx-gxjl-idqnomt-lnoceajwkp-ydwlkqilp/

Velveteen produces more than 90% of the national production of corduroy. It was researched from imported callen dough in the middle of the Meiji era and can be produced in the 28th to 29th years of the Meiji era. Initially, corduroy was popular as a material for hanao.

<Corduroy> Source: https://www.happycloth.co.jp/shop/products/detail.php?product_id=2055

Western area of Shizuoka prefecture. Along with Quanzhou and Mikawa, it is one of Japan’s three largest cotton fabric producing areas. Wide fabrics occupy 80%. In an era when highly productive looms were in full swing, it is a production area with a large number of shuttle looms. Traditional entwined weaving techniques remain.

<Shuttle loom> Source http://textile-tree.com/tex/sanchi/shuttle-loom2/

It has the characteristic of being able to consistently produce from primary processed products to final products in the area centered on Gamagori City, which is said to be the place where cotton was introduced. We have state-of-the-art looms such as air jets, rapiers, and sulzers, as well as narrow power looms, and make full use of dobby and jacquard to produce textiles in a wide range of fields such as interiors, bedding, and materials.

Owari Province, commonly known as Owari, is famous for producing woolen fabrics. It is said that it started with hemp and silk and was mainly made of cotton fabric until the early Meiji era. After the Great Noo Earthquake of 1891, it became difficult to cultivate cotton, and after struggling to return it to woolen fabrics using imported yarns, it developed into a major production area for woolen fabrics. A division of labor system has been established, enabling a wide variety of small lots and short cycles.

<Shonhel loom> Source: https://hatarakuka.jp/blog/9116

It is a major production area of synthetic fibers centered on high-density woven fabrics for sports and the outdoors. Textiles from the same production area are widely used not only for clothing but also for industrial materials such as car seats, personal computers, and building materials.

It is a production center of high-class hemp textiles known as <Omi Jofu>. It is said that it was blessed with high temperature and high humidity natural conditions suitable for hemp weaving from the humidity generated by Lake Biwa. It also prospered as a production center near Osaka and Kyoto. From around 1975, we switched from narrow width for kimono to wide width to support hemp production in Japan.

<Omi Jofu> Source: http://jimoto-b.com/815

Since it was a land suitable for cotton cultivation, it became famous as a production center of <Izumi cotton>. The area centered on Izumiotsu, which specializes in blanket production due to the military demand of the Sino-Japanese War, accounts for 90% of Japan’s blanket production.

<Izumi cotton> Source: http://izumimomen.com/diarypro/diary.cgi

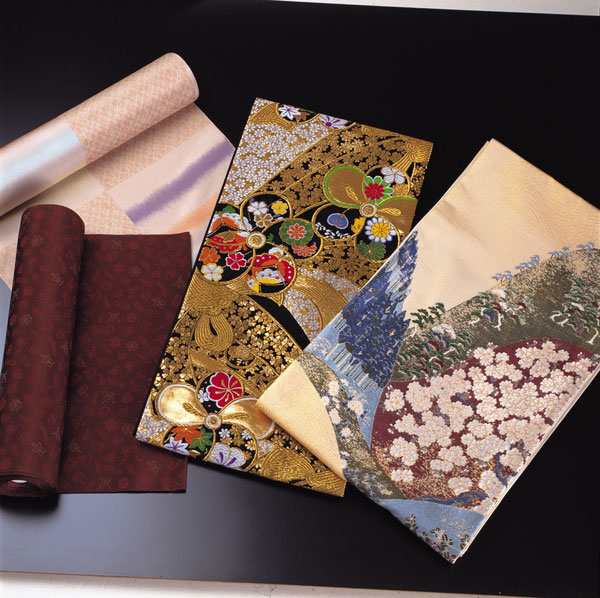

Japan’s largest producer of silk fabrics. We boast a 70% share of white fabrics for kimono. It was created based on the twisting technology brought from Nishijin, Kyoto during the Edo period, and developed as a production center at the beginning of <Tango Chirimen>. Since the middle of the Showa era, the production of yarn-dyed fabrics (obi, ties) has been active, and it is a comprehensive production area of silk fabrics together with post-dyed fabrics (crepe).

<Tango Chirimen> Source: https://thetango.kyoto/luxury/tangochirimen01/

Yarn-dyed cotton fabrics have a 70% share of the domestic market. <Banshu weave> is a thin yarn-dyed cotton fabric used for shirts, etc., and has gingham check and stripes. It is a production area equipped with a system and technology to handle large lots.

<Banshu Ori> Source: https://clocomi.jp/2016/06/%E6%92%AD%E5%B7%9E%E7%B9%94%E3%81%AE%E9%AD%85%E5 % 8A% 9B-02 /

Kojima, Okayama Prefecture (Bizen), Fukuyama City, Hiroshima Prefecture (Bizchu) Bingo districts are collectively called the Sanbi Producing Area.

Kojima is famous as the birthplace of domestic jeans. In addition, it is a production area with a strong impression of durable cotton fabrics such as school uniforms and workwear. Since the 1960s, it has established itself as a production center for domestic jeans in areas where cotton fabrics were originally flourishing. Many companies have very high skills in jeans dyeing and post-processing.

I also posted about denim on my previous blog! Https://www.knitmag.jp/28757

Towels came into Japan after the Meiji era. Until then, weaving white cotton fabrics and flannel fabrics, but weaving of towels began in 1952 and became the largest in Japan around 1991.

<Air jet loom> Source: https://www.imabari-kinsei.com/flow/

It is the production center of the thick silk fabric <Hakata-ori> used for obi. It is said that Hakata merchants went to China to learn and improve textile techniques. Many of them are delicate and graceful as gifts to the Edo Shogunate and the imperial family.

<Hakata-ori> Source: https://shikinobi.com/hatataori_dentou

How was it? It just got longer!

Maybe there were some familiar areas? I think.

Currently, there are only a few production areas that continue to be called production areas, but as one of the people involved in the textile industry.

Let’s be confidently involved as an industry that has been the driving force behind Japanese industry!

see you!

2023年11月29日

2023年11月9日

2023年11月7日

2023年11月1日

2023年10月26日

2023年10月24日